COMPOSITE FRIEND SISAL / POLYESTER TREATED IN SURFACE

DOI:

https://doi.org/10.15628/holos.2011.670Resumo

The use of composites in manufacturing equipment and products is taking a very important space in the industry in general. Moreover these materials have unique characteristics when analyzed separately from constituents who are part of them. However it is know that cares must be taken in their manufacture, as the use of appropriate process and the composition of each element, in addition to adherence fiber / matrix, which is a major factor in obtaining of the final mechanical strength of the product. One should also take into account whether the composites are environmentally friendly. For this reason, in this work, a composite partially ecological was made, using as reinforcement, a sisal woven and, as matrix, the polyester resin. Seeking to improve the adherence fiber / matrix, a treatment in sisal woven was performed with aqueous solution of sodium hydroxide (NaOH) at a concentration of 3%. The composite subjected to this treatment presented, in bending test, a better mechanical performance, with an increase of 27% in the flexion strength and of 54% in maximum strain, but there was a reduction of about 15% in its flexural modulus.Downloads

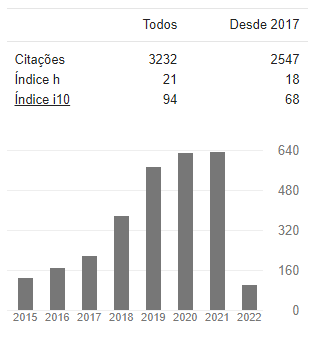

Não há dados estatísticos.

Downloads

Publicado

26/09/2011

Como Citar

Santos, J. K. D., Cunha, R. A. D., dos Santos Felipe, R. C. T., Felipe, R. N. B., & Medeiros, G. (2011). COMPOSITE FRIEND SISAL / POLYESTER TREATED IN SURFACE. HOLOS, 4, 102–111. https://doi.org/10.15628/holos.2011.670

Edição

Seção

ARTIGOS